Yeti and Swell are two well‐known brands in the insulated drinkware market, each offering a range of products in various sizes and designs. But Take a look at the current pricing, which reveals distinct ranges for each brand. You will find Yeti is more expensive than Swell. For example, Yeti’s 20‑ounce drinkware—such as the Rambler Tumbler with MagSlider lid—is listed on some major retailers at prices between approximately $35 and $42, while Yeti’s larger models, like the 30‑ounce version, can be found in a similar or slightly higher range.

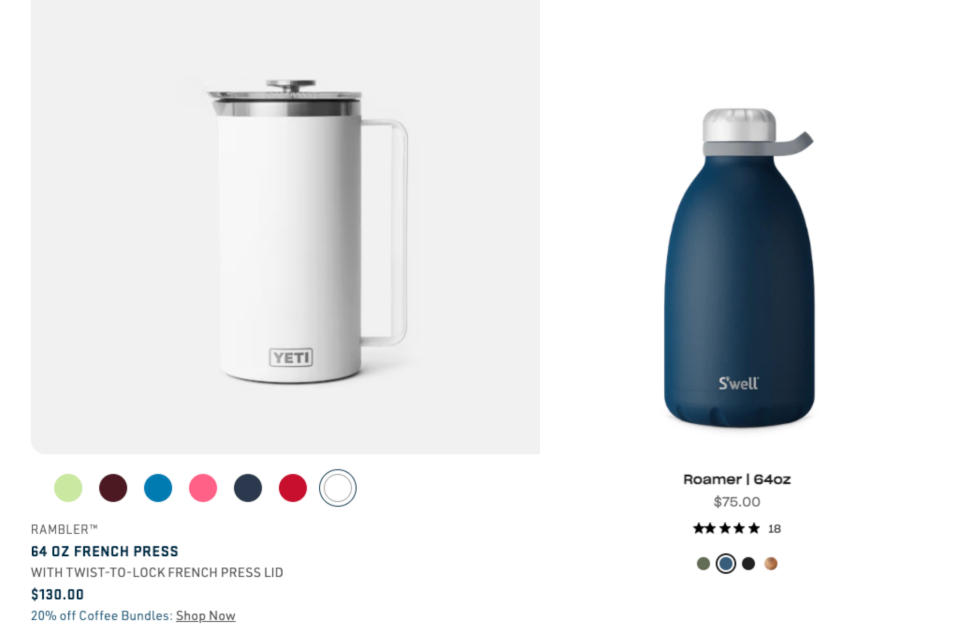

The most expensive ramber on Yeti is priced at $130, while a romaer of the same capacity on swell is $75.

Brand buyers and end users alike might wonder why Yeti is more expensive than Swell. Today, let’s take a step back and look at the factors from a manufacturer’s perspective.

Manufacturing Costs: Different Use Cases Lead to Variations in Materials and Craftsmanship

The manufacturing process plays a crucial role in determining product pricing. While both Yeti and Swell use stainless steel and offer vacuum-insulated bottles, the construction, durability, and intended use cases result in cost differences.

Swell: Prioritizing Lightweight and Stylish Design

Swell bottles are designed with urban consumers in mind, emphasizing style and portability. While they do use stainless steel, their manufacturing process focuses on making bottles lightweight and visually appealing.

1. Lightweight and Fashion-Oriented Craftsmanship

Swell bottles prioritize a sleek and modern design. The brand emphasizes thin-walled stainless steel construction, which reduces weight and enhances portability. While this approach makes them highly convenient for daily use, it may not offer the same level of durability as a more rugged outdoor bottle.

2. Smaller Capacity Options

Most Swell bottles come in relatively compact sizes, with large-capacity options being less common. This design choice aligns with the brand’s focus on office workers, commuters, and casual users who don’t need oversized drinkware. Since smaller bottles require fewer raw materials, this also keeps production costs lower.

3. Vacuum Insulation Tailored for Daily Use

While Swell bottles do incorporate vacuum insulation to maintain temperature control, they are primarily designed for everyday activities rather than extreme environments. Their insulation performance is adequate for work, gym, or travel, but may not be as robust as Yeti’s offerings.

4. Fashion-Forward Aesthetic

Swell focuses on stylish, colorful, and minimalist designs that complement an urban lifestyle. They frequently introduce new patterns, textures, and finishes to appeal to fashion-conscious consumers. However, frequent style updates mean managing a wider SKU range, which can introduce additional logistical costs and limit economies of scale in manufacturing.

Yeti: Built for Durability and Extreme Conditions

In contrast, Yeti products are engineered for outdoor enthusiasts and professionals who require extreme durability and performance.

1. Heavy-Duty Stainless Steel Construction

Yeti bottles and tumblers are made with thicker stainless steel and reinforced construction, making them more resistant to drops, dents, and wear. This robust build contributes to higher material costs compared to Swell’s lightweight approach.

2. Large-Capacity Options

Yeti offers many large-capacity options, catering to hikers, campers, and professionals who spend extended periods outdoors. Bigger sizes mean more material use, further increasing production costs.

3. Advanced Insulation Technology

Yeti’s double-wall vacuum insulation is designed to perform in extreme environments. Whether in freezing cold or scorching heat, Yeti products maintain beverage temperatures for extended durations. The extensive research and development behind this insulation technology contribute to a higher price tag.

4. Attention to Detail: Leakproof Lids and Non-Slip Bases

Yeti drinkware often features additional design elements such as leakproof lids, non-slip bases, and ergonomic grips—features that improve usability in rugged conditions. These extra features increase production complexity and cost, but they are crucial for outdoor users who demand reliability in their gear.

Brand Positioning: Different Markets, Different Pricing Strategies

Beyond manufacturing costs, the way Yeti and Swell position themselves in the market plays a significant role in pricing.

Yeti: Premium Outdoor Gear

Yeti targets outdoor enthusiasts, campers, and professionals who require high-performance gear in extreme conditions. Because durability, insulation, and reliability are non-negotiable for this demographic, they are willing to pay a premium for superior quality. Yeti also invests heavily in branding, with a rugged, adventure-driven image that reinforces its reputation as a premium brand.

Swell: Stylish Everyday Use

Swell, on the other hand, markets itself as a lifestyle brand, appealing to urban professionals and trend-conscious consumers. The emphasis on design variety means the brand frequently updates its product lines to align with fashion trends. However, frequent updates require managing multiple SKUs, which can impact economies of scale. To keep pricing competitive, Swell optimizes its production process and material use, avoiding the high costs associated with extreme durability.

Consumer Acceptance:

Another reason for the price disparity is the differing expectations and purchasing behaviors of each brand’s target market.

Yeti’s primary audience consists of outdoor adventurers, hikers, campers, and even workers in demanding environments. For these users, high performance is a must. The ability to keep drinks hot or cold for extended periods, withstand rough handling, and prevent leaks is worth the premium price. Yeti buyers are often brand-loyal and view their purchases as long-term investments rather than fashion statements.

Swell appeals to young professionals, fashion-conscious consumers, and those who prioritize aesthetics alongside functionality. While they value insulation performance, they are generally more budget-conscious and price-sensitive than Yeti’s audience. Swell’s success lies in offering a balance between style and practicality at a more accessible price point.

Brand product pricing is influenced by a range of factors, including manufacturing costs, target consumer demographics, applicable usage scenarios, and overall brand positioning. As manufacturing costs rise, the risk borne by the brand also increases, since higher production expenses necessitate a more substantial investment with corresponding expectations for performance and market success. Therefore, finding ways to reduce procurement costs without sacrificing quality is a continual challenge for brand owners, as it directly affects their risk management strategies and ultimately helps maintain competitive pricing in the marketplace.

How to reduce the water bottle manufacturing cost for brands?

When it comes to optimizing sourcing costs for water bottles, it’s essential to have a clear understanding of the target audience for brands, as different consumer groups have varying levels of acceptance regarding product quality and pricing.

Know your Targeted Audience

A deep understanding of the brand’s target audience is the cornerstone of effective procurement cost management. Different consumer audiences have unique expectations regarding product quality, durability, and design aesthetics.

For instance, the water bottle needs of an outdoor hiker are vastly different from those of an urban commuter. By carefully analyzing user profiles and market research, we can tailor our manufacturing processes and material choices to meet these varied demands.

This targeted approach allows brands to invest only in the necessary premium materials and specialized production techniques where they truly add value, thereby avoiding unnecessary costs that do not align with consumers’ specific needs.

Maximize the manufacturing quantity per batch

Another pivotal strategy for lowering procurement costs lies in optimizing production volumes. By increasing the production quantity for each batch, manufacturers tap into the benefits of economies of scale.

Producing a larger quantity of a single SKU significantly reduces the per-unit cost because fixed overheads and manufacturing expenses are distributed over a higher number of units. This strategy not only helps us negotiate better pricing with our raw material suppliers but also streamlines our production process. As a result, we can provide a competitive price point for our water bottles while still upholding the high quality and performance our clients’ expections.

Choose the material and technology accordingly

Materials and process methods are key factors that significantly impact manufacturing costs. Brands typically select materials and tailor thermal performance based on their brand positioning and the specific requirements of their target audiences. This strategic approach ensures that every product not only meets performance expectations but also aligns with the overall image and quality standards that consumers have come to expect.

316 stainless steel is more expensive than 304

For example, while 304 stainless steel is a popular and cost-effective option, we might choose 316 stainless steel for products designed for extreme outdoor conditions because it offers superior corrosion resistance and durability—even though it is more expensive.

Real lead-free welding technology vs. lead-free solder flux

The real lead-free welding process requires using stainless steel balls. This method creates minimal indentation (tiny “dimples”) at the cup base, eliminating the need for unsightly cover-up patches.

Most other water bottle manufacturers are using cheaper glass-bead lead-free solder flux end up with larger dimples, forcing the bands to add stainless steel stickers to hide imperfections. For brands choosing between these methods: If aesthetics and seamless design are priorities, the steel-ball approach is worth the investment. If cost matters more, traditional glass-bead welding remains an option.

Different thermal performance

Some insulated water bottles can only keep water warm for 6 hours, while some thermos tumblers can keep water warm for 12 hours and cold for 24 hours. The differences lie in the thermal technology when manufacturers are making the double-wall insulated stainless steel.

Thermal performance is influenced by several factors, including material thickness, vacuum insulation technology, and additional enhancements such as inner copper coating or aluminum foil within the vacuum layer. These features improve heat retention but also increase production costs. For insulated bottles designed for outdoor use or premium teacups targeted at high-end consumers, manufacturers often incorporate these more advanced and complex insulation techniques to meet higher performance expectations.

New Cap Designs Cost More

Another factor that can drive up production costs is the bottle cap design. If a brand opts for a completely new cap featuring an innovative, easy-to-sip spout, this choice requires a full remolding process for all the plastic and silicone components involved. Such a redesign significantly increases manufacturing expenses.

Conversely, if a buyer selects a cap model that already exists within the manufacturer’s collection, there’s no need for additional remolding. This approach dramatically cuts down on sourcing costs, making it a preferred option for many ODM orders. Brands can simply choose an existing mold, then customize the final product by changing the color of the cap and bottle and adding their logo. This strategy strikes a balance between achieving a unique look and maintaining cost efficiency.

By clearly defining the target audience, scaling production volumes, and meticulously selecting materials and manufacturing processes that align with the brand’s positioning, manufacturing can deliver water bottles that stand out in both quality and performance.

But here’s the good news for brand buyers, gift companies, and corporate gift planners: premium quality doesn’t have to come with a “big-brand” price tag. While Yeti and Swell invest heavily in branding and rely on large MOQs to control cost, we work differently. As a stainless steel drinkware gifting provider, we work with the best water bottle manufacturers to bring the same grade of double-wall vacuum insulated bottles that major outdoor and lifestyle brands use—but we also keep a wide range of in-stock tumblers and mugs that are ready for logo printing and fast shipment. Whether you need custom gifts for an event, a corporate program, a promotional campaign, or a retail test order, our low starting order quantities make it easy to launch your own branding project without the inventory pressure or upfront risk. Whether you need corporate gifts, promotional merchandise, or private-label retail products, you can start with low minimums, fast turnaround, and full customization. In other words, you get big-brand quality—without big-brand limitations.